Floating cover for slurry silos

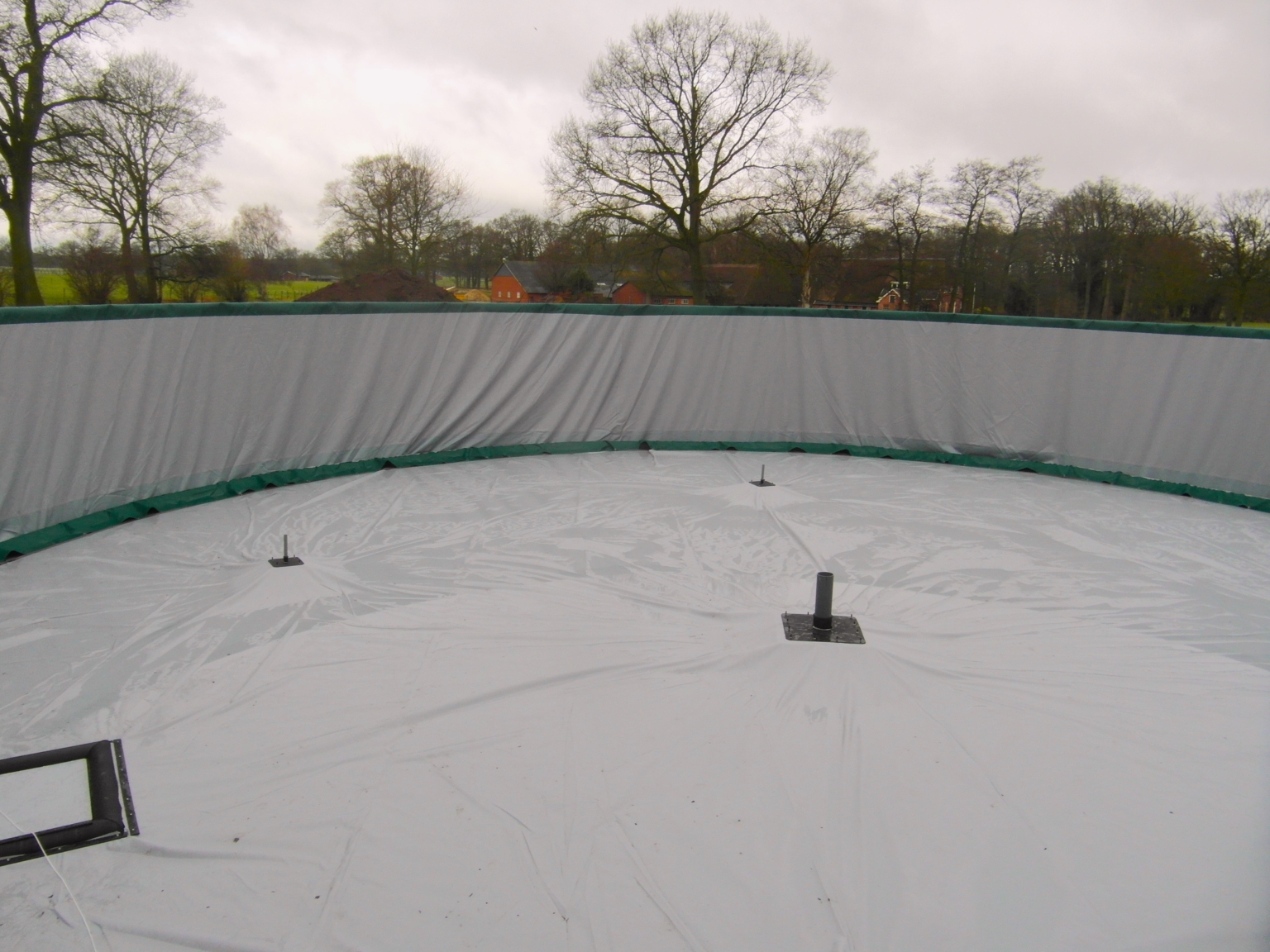

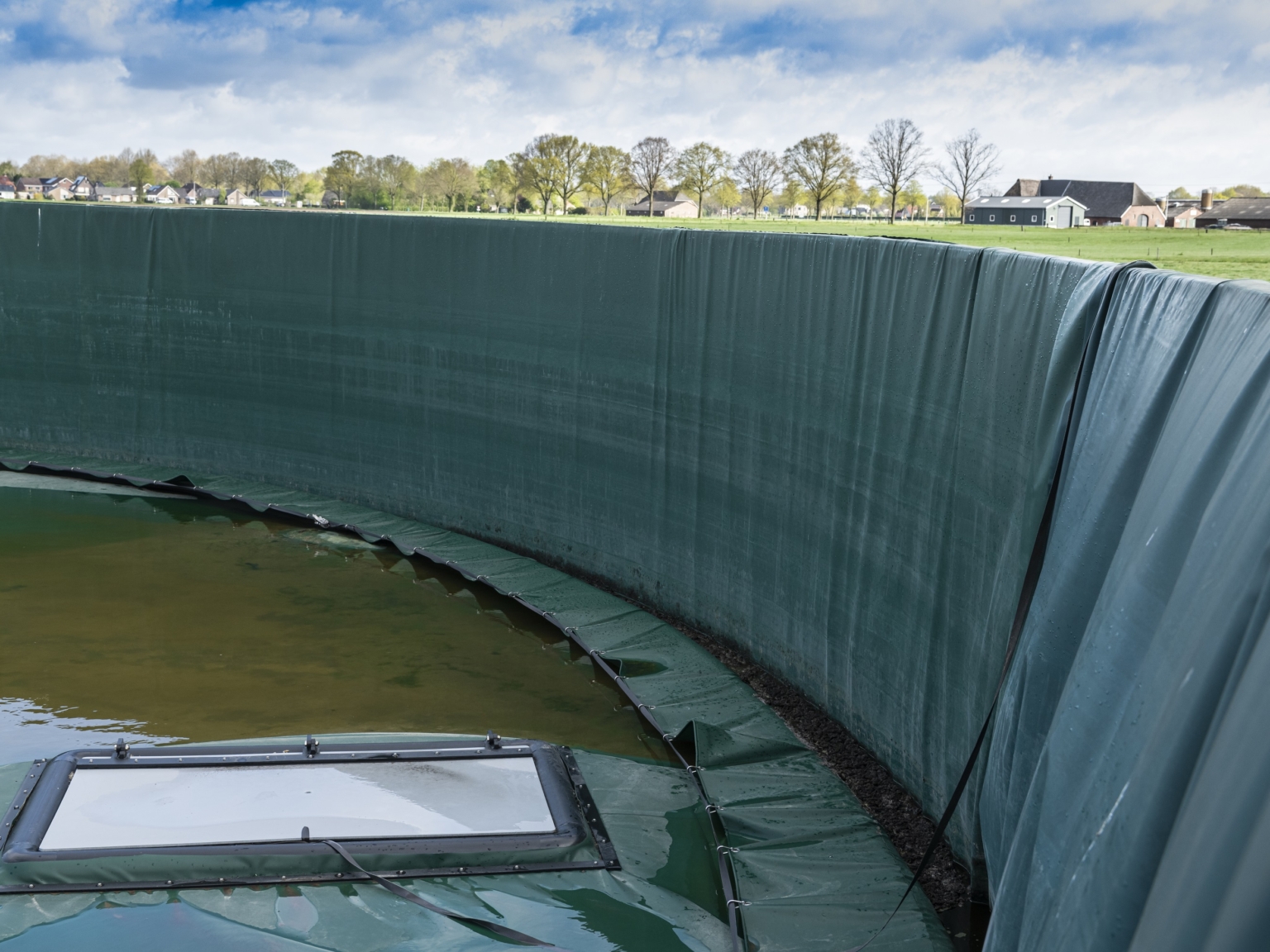

For slurry silos that cannot accommodate a tension cover, such as mesh silos, floating covers are a superb alternative. Tailored to fit, these covers rest on top of the slurry, adapting to its volume fluctuations. Pumping off rainwater that accumulates on the cover ensures it doesn’t mix with the slurry, optimising the silo’s storage efficiency.

Construction of a slurry silo floating cover

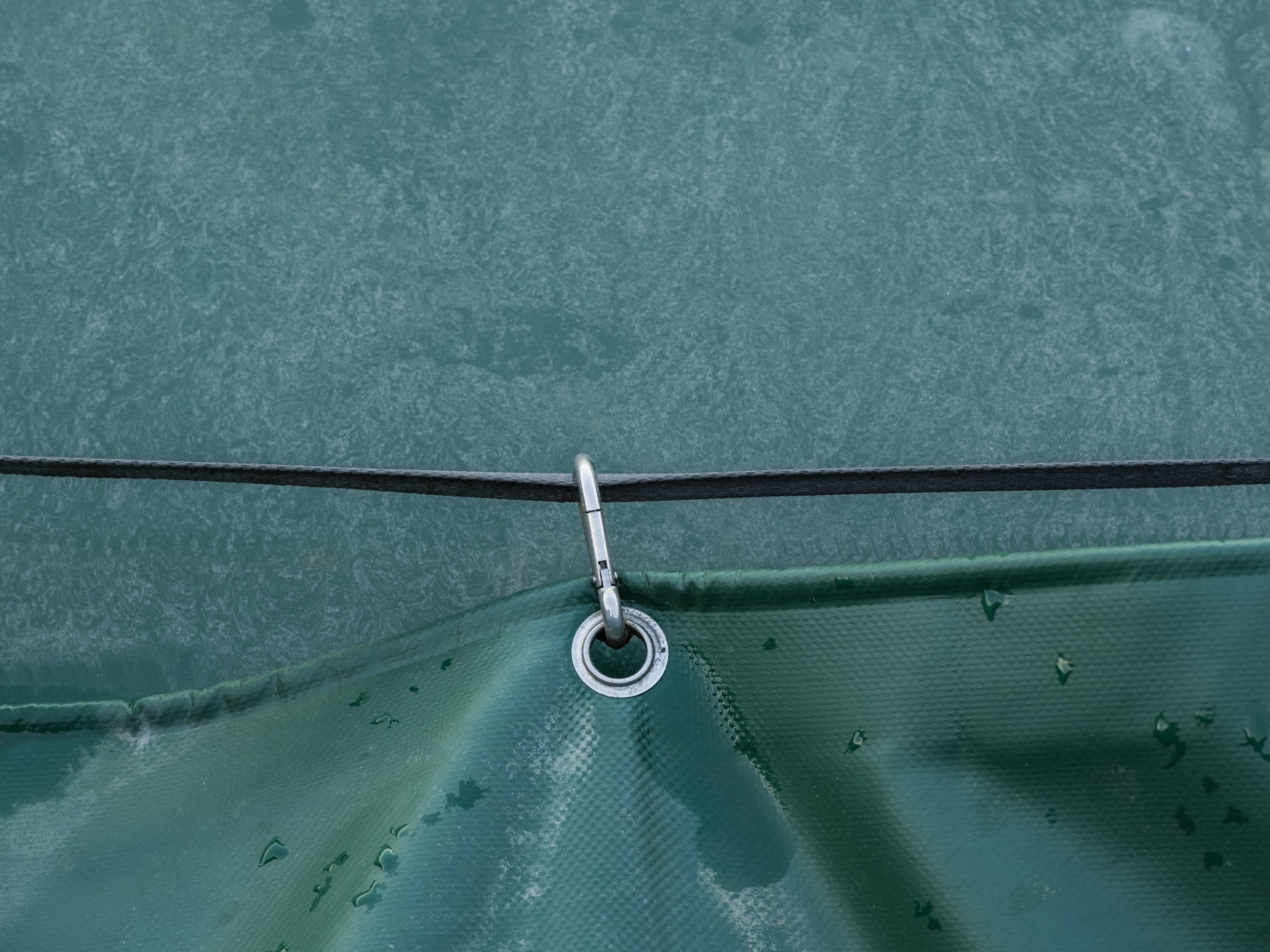

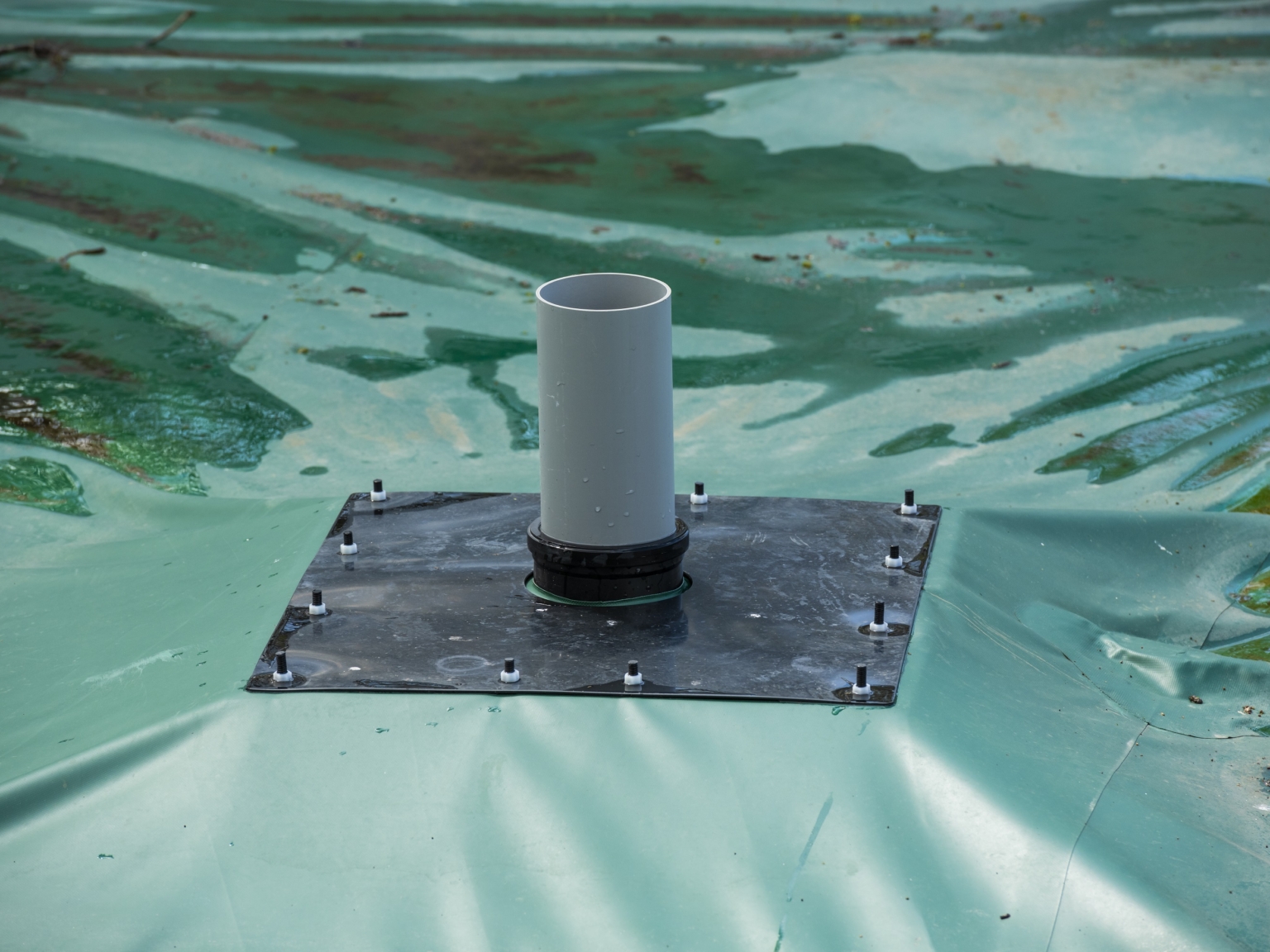

Constructed from durable PVC geomembrane wrapped around a ring-shaped PVC pipe secured with carabiners, the floating cover incorporates floats underneath for gas release. Additionally, a mixing hatch may be added to the cover, suitable for enhancing the mixing process from outside the silo. This feature, along with mixing hatches, access ports, and gas venting floats, is fitted during the installation process on site.

- Economical cover solution

- Ensures full use of the silo’s storage space

- Does not exert pressure on the silo structure