Sealing of landfills

To prevent soil contamination, air, and water pollution, landfills must comply with stringent laws and regulations, as set out in the Environmental Management Act and the Landfill Decree. Among other requirements, these regulations mandate that heavy metals, toxic chemicals, and leachate must not leak into the groundwater and soil.

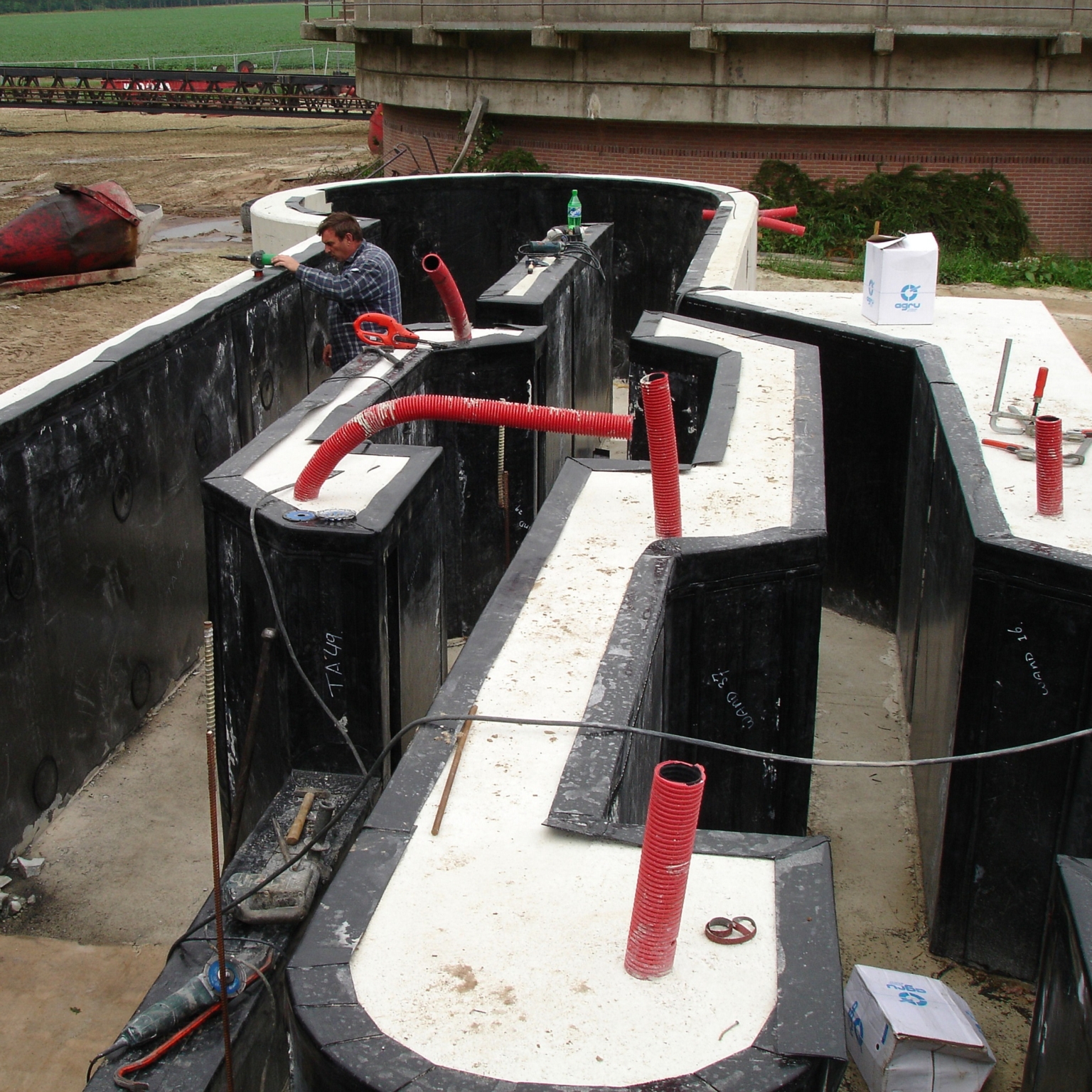

Genap has years of experience in covering these landfills with an environmentally protective, synthetic membrane. Typically, a 2 mm HDPE membrane is used for this purpose, as prescribed by the current guidelines for the use of synthetic constructions for environmental protection and/or the landfill decree on soil protection.

Yet, each project also has its specific requirements. Our in-house engineers possess the knowledge and experience to provide detailed advice on this matter, including any additional provisions such as drainage mats or geogrids, which may be necessary for a stable construction of the slope.

Genap supplies the required synthetic materials and installs the structures, done by our own assembly team. At this point, we have extensive experience both domestically and internationally. The seal is subsequently assembled on-site. The 7 metres wide foil seal is then assembled to the projects required dimension and shape. Outlets and connections for pipes, concrete structures, and drop inlets can be customized.

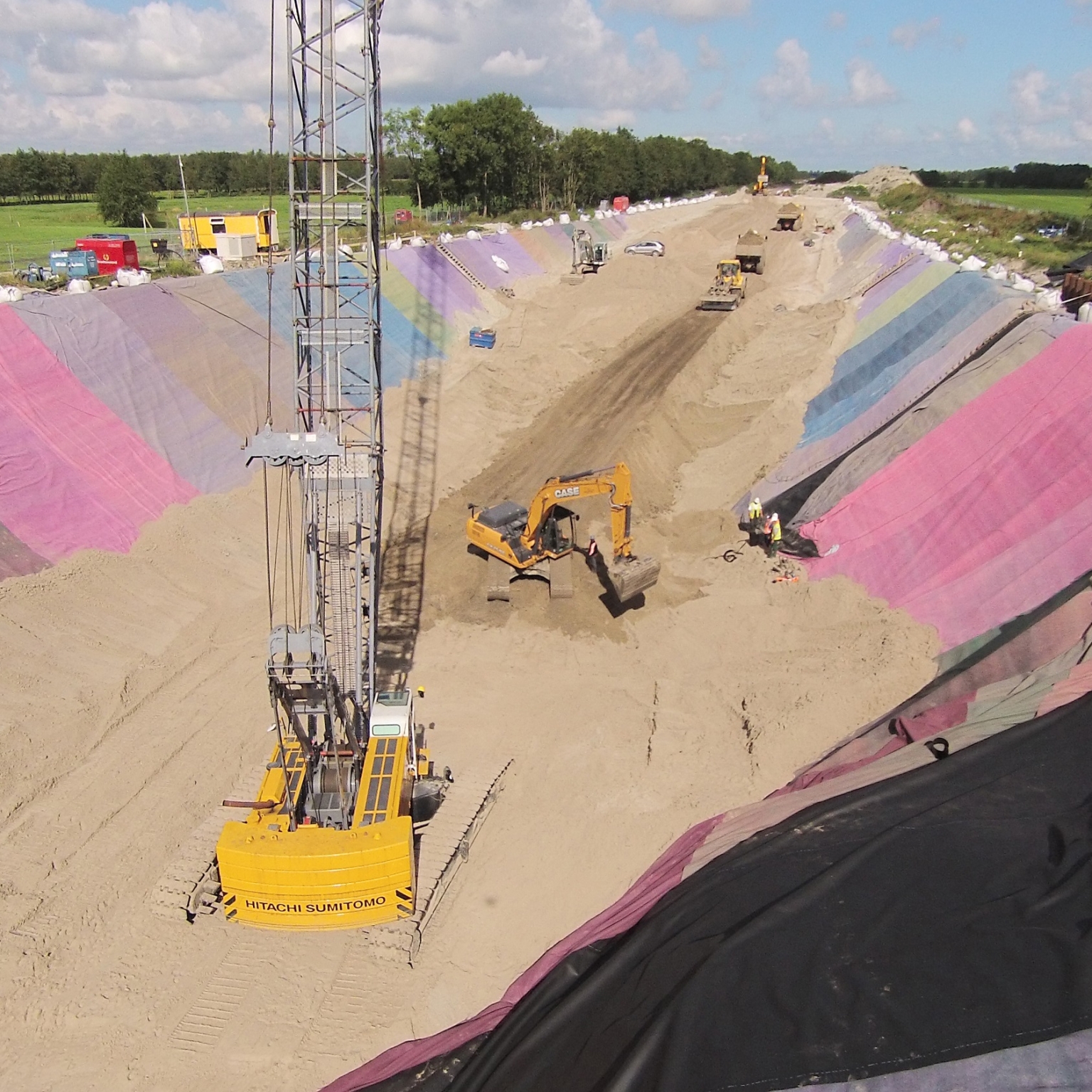

Bottom protection for landfill sites

Bottom geomembranes play a crucial role in landfill management, aiming to prevent leakages and protect groundwater from contamination. These geomembranes are applied beneath the waste mass and serve as an additional barrier against the leakage of fluids, such as leachate, which can form as a result of rainwater percolating through the waste. On top of this underseal, waste can be deposited safely.

Semi-permanent protection for landfill sites

A semi-permanent geomembrane is often used during the operational phase of a landfill, even before the landfill is fully filled. It’s a temporary cover that can be periodically adjusted or renewed as the landfill expands. The aim is to reduce the exposure of the waste to atmospheric conditions and to limit the formation of leachate during the operational lifespan of the landfill.

Final sealing of landfill sites

Once the landfill is full and decommissioned, it is also sealed from the top with a permanent closure. This final seal aims to isolate the landfill from the surrounding environment and prevent the long-term spread of contaminants after closure. This covering is designed to minimize rainwater infiltration and ensure the stability of the landfill. A final cover consists of multiple layers, including clay and synthetic materials, to form an effective barrier against leachate formation. You could opt for a material which has a structure that prevents the sand layer on the slope from sliding.

A new development in the final sealing of landfills is the ClosureTurf®. This is an attractive and affordable three-component covering system for waste disposal sites that prevents erosion and controls gas emissions.

- KIWA-certified construction

- Partner of the most renowned contractors

- Unique expertise and experience