Bottom seals for tank terminals

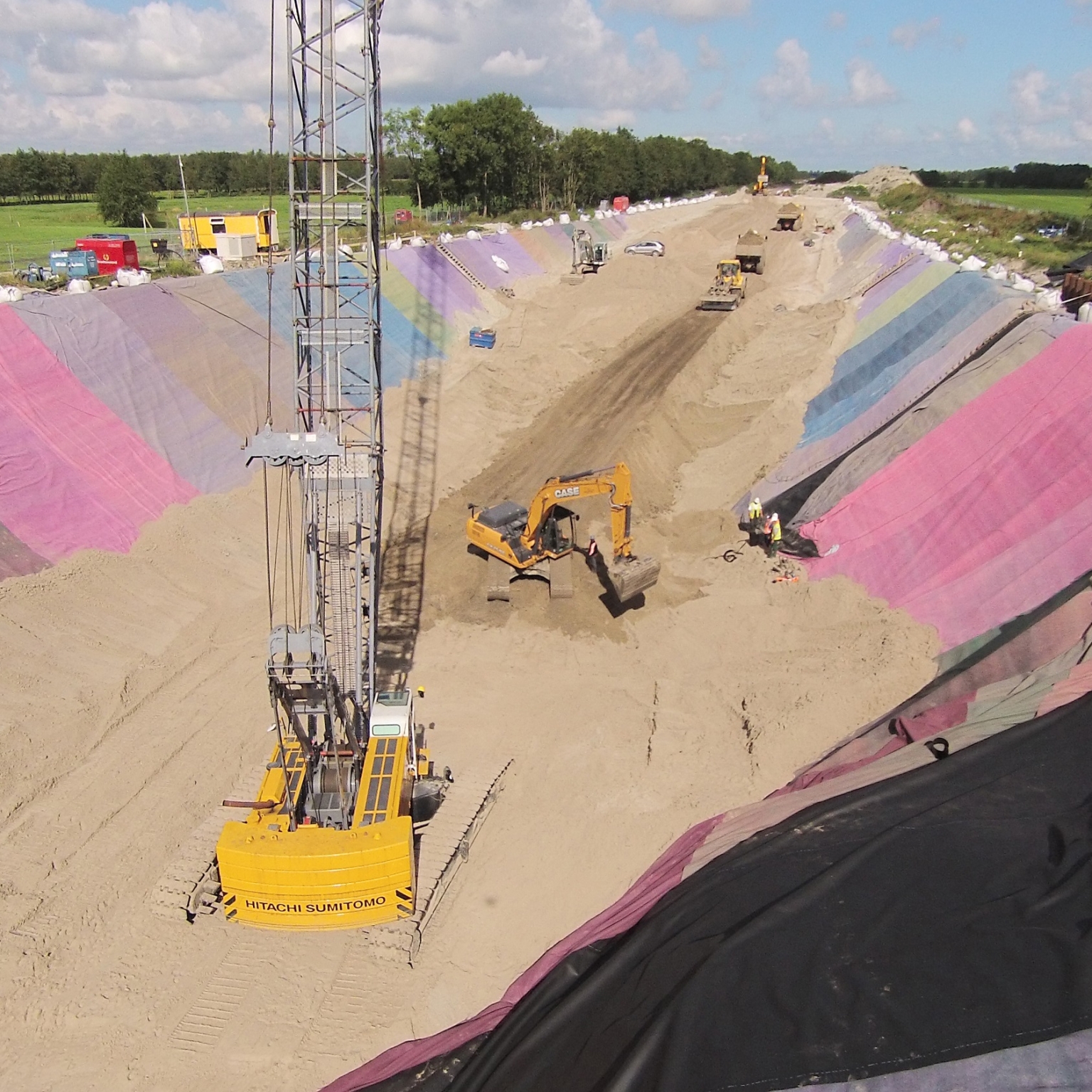

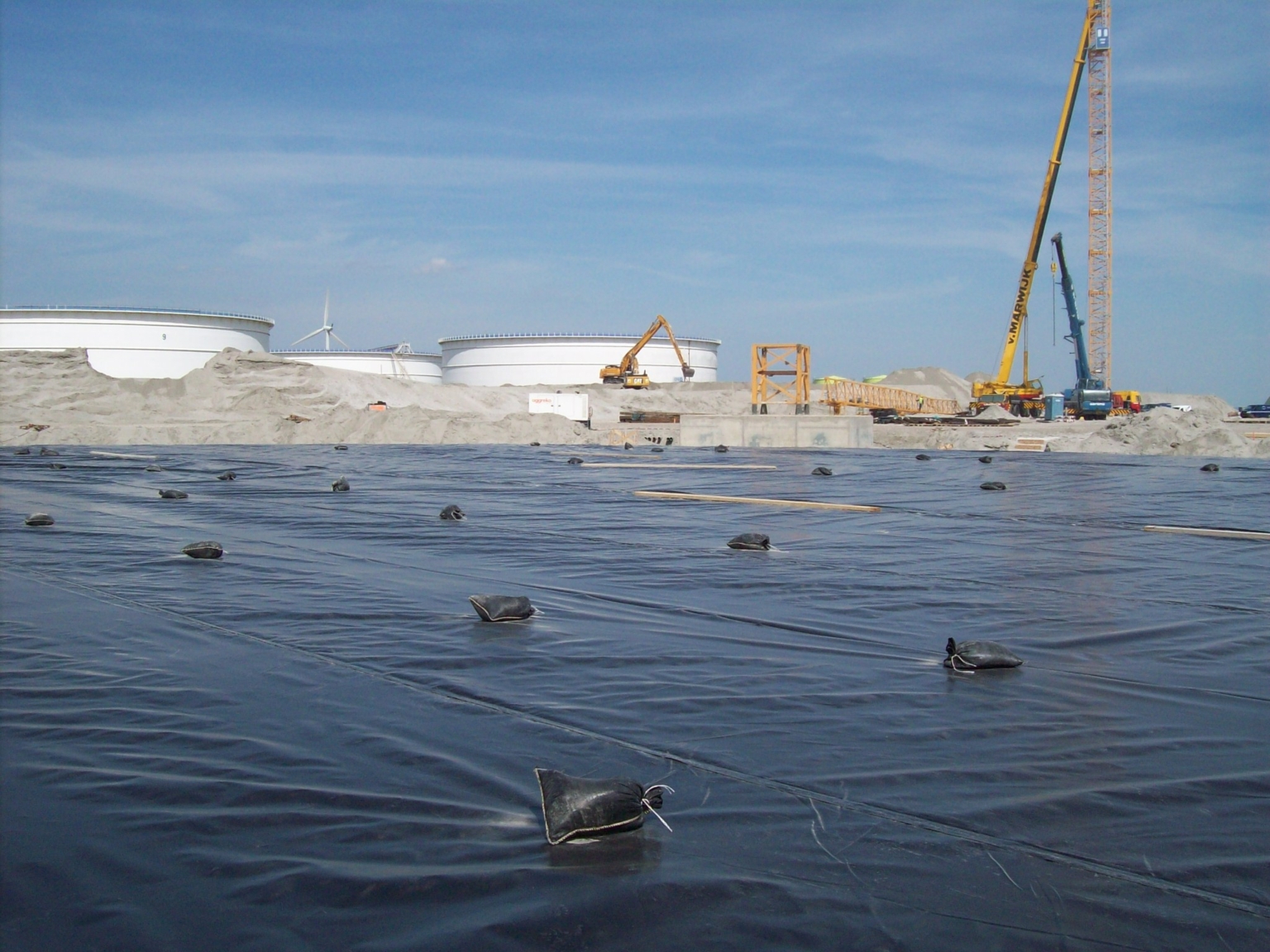

Bottom sealings at tank terminals are essential for maintaining facility integrity and safeguarding the environment. These terminals store vast amounts of liquid substances, including fuels and chemicals, necessitating effective measures against leaks and soil contamination. Serving as a crucial barrier, bottom sealings underneath the storage tanks prevent any potential leaks or spills from reaching the soil beneath. This precaution is key to preventing soil contamination and protecting the quality of groundwater. Integrated with comprehensive tank bottom protection strategies, bottom sealings include the use of protective coatings and liners at the tank bases to avert corrosion and enhance the tanks’ longevity.

100% oil-resistant geomembranes

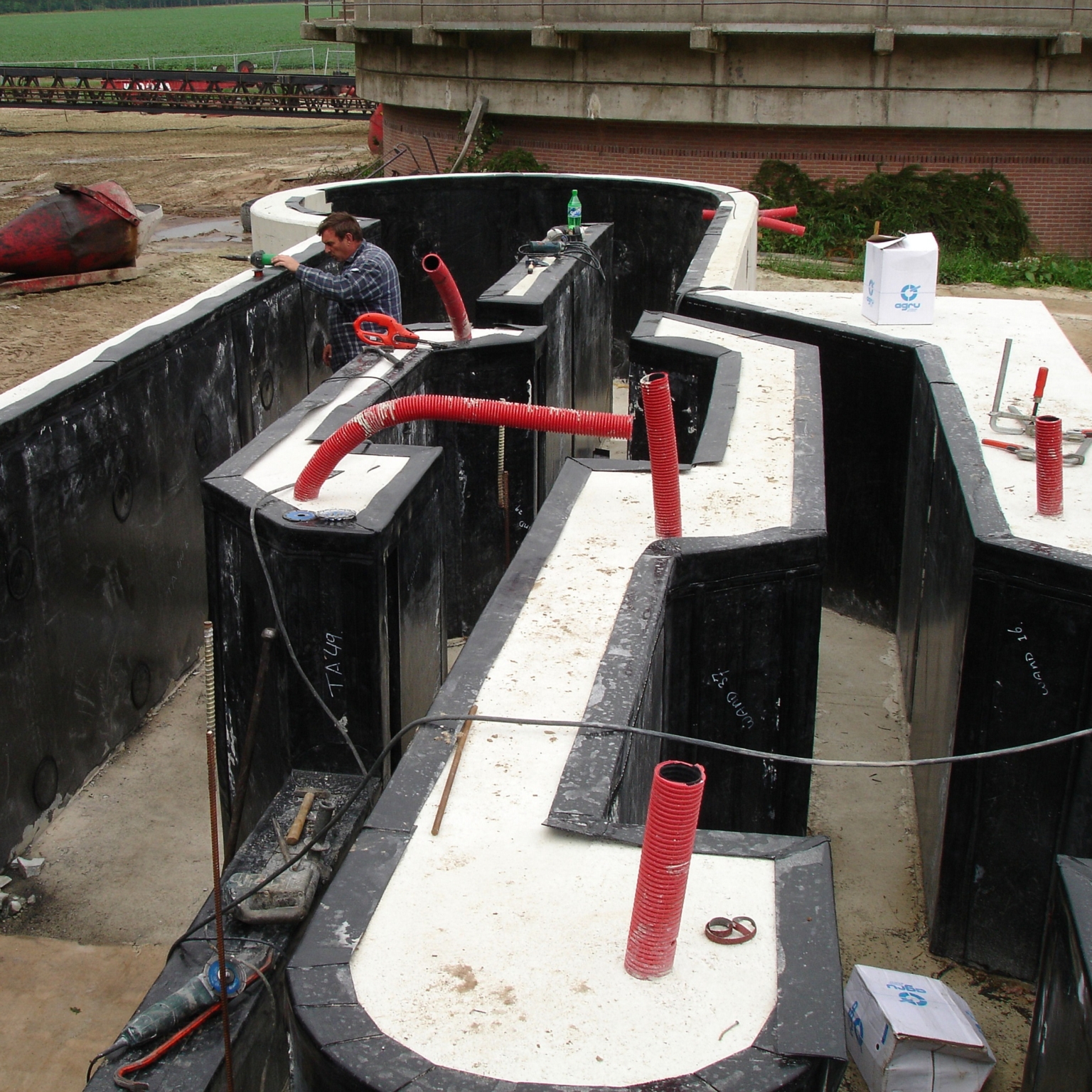

Bottom seals for tank terminals are usually made of a 2mm HDPE membrane. But Genap’s exclusive and 100% oil-resistant material Genatex® 1150XR is rapidly catching on.

The benefits of Genatex® 1150XR

- The material is 100% resistant to crude oil and kerosene, unlike HDPE.

- The 1 mm-thick material is reinforced and is allowed to be folded.

- the material can be prefabricated into large sheets or into complete sheets (up to 2,500m²).

- The membrane construction can often be installed within one day.

- The thermal expansion is very low (22x lower than HDPE), making crease formation less likely to occur.

- Genap has now successfully installed the durable Genatex® 1150XR seals for various national and international clients.