Dry installation

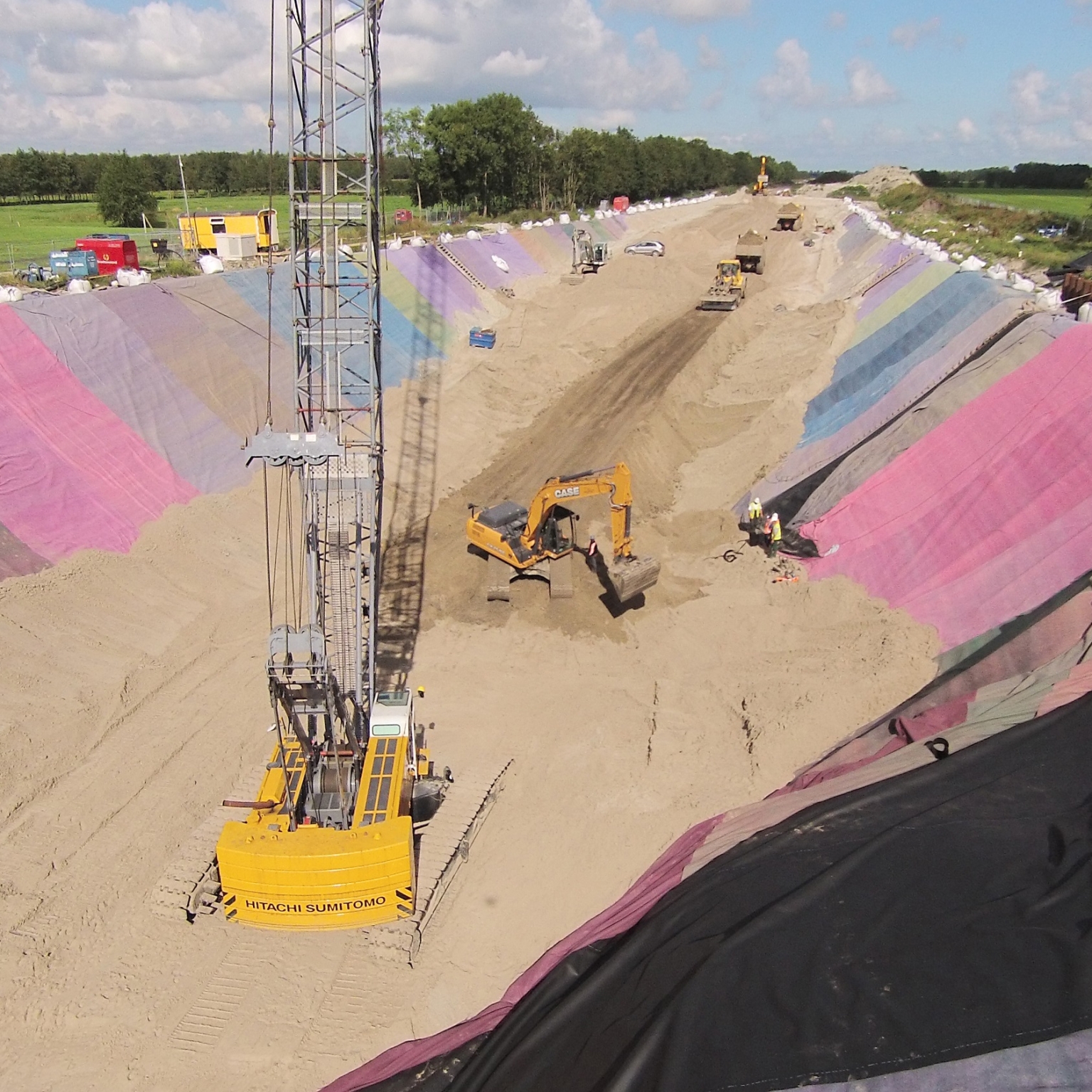

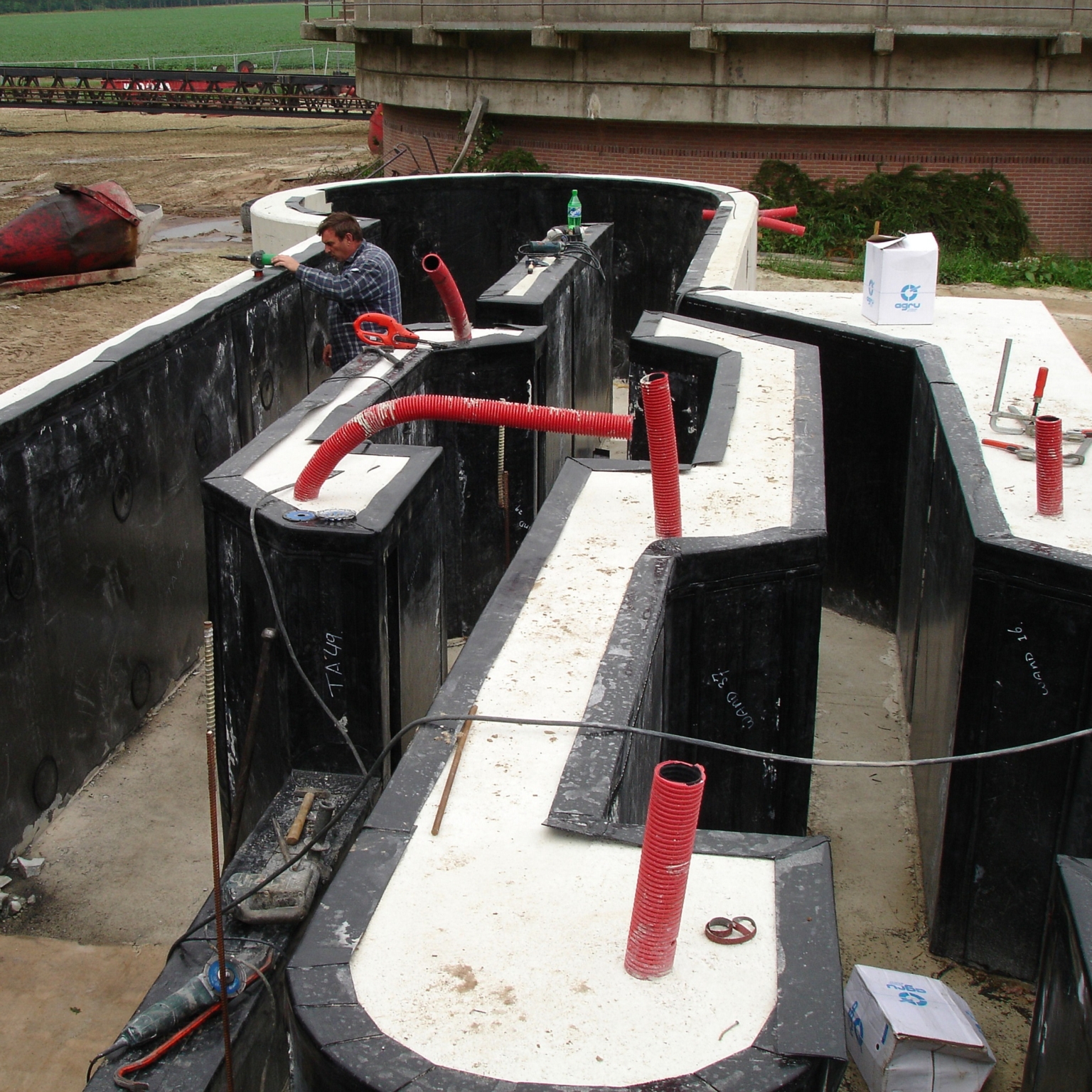

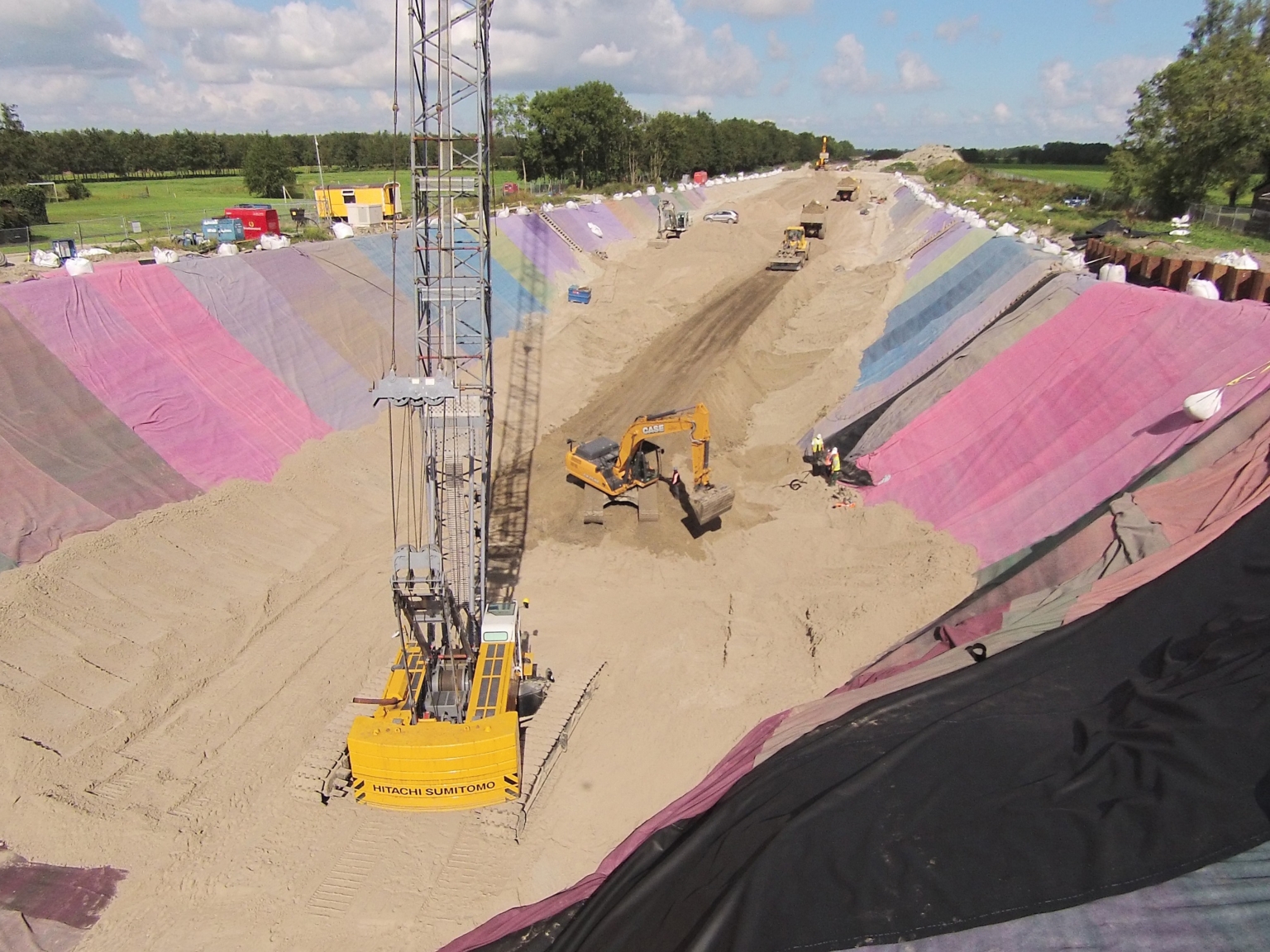

Unlike submersion, dry installation is a proces wich uses large rolls of (LLD)PE plastic membranes, approximately seven metres wide. These large rolls are welded together on-site. Connections to the concrete structures are made using a modified PE membrane (known as MP 950-20). Unlike the base material, this synthetic material can be folded and equipped with a rope hem and/or holes for clamping profiles.

Should the project conditions allow for it, a portion of the sythetic structure can be pre-assembled in our manufacturing facility. The major advantage of this is that the geosythetics can be welded under controlled conditions. The welds and membrane are then better protected from external conditions, enhancing the durability of the welds and the membrane against external factors.

To shield against substrate or backfill sand, protective membranes are commonly employed. The selection of the protective membrane type hinges on the level of contamination present in the sand. Typically, a non-woven protective membrane weighing 500g/m² is chosen.