"*" indicates required fields

Understanding the versatility and engineering of steel silos

At Genap, we take pride in our extensive expertise in manufacturing and supplying high-quality steel water silos tailored for professional growers. Our in-depth knowledge of material science, engineering, and environmental considerations allows us to provide reliable and versatile water storage solutions. Here, we share some insights into the key features and benefits of our steel silos.

Advanced material selection and coatings

Our steel silos are crafted from premium materials, ensuring durability and longevity. We utilize steel thicknesses ranging from 0.8 mm to 1.85 mm, with corresponding strengths of S280 for thinner sections and S350 for thicker sections. This selection of materials, based on static calculations, guarantees that our silos can withstand various stresses and environmental conditions.

To enhance corrosion resistance, our standard silos feature a ZM200 galvanised coating from Arcelor, which exceeds the industry standard. This coating not only protects the silos from corrosion but also ensures their structural integrity over time. For those needing additional protection, especially when the silos are buried, we offer optional coatings to fortify the bottom rings or the entire silo.

Flexible dimensions and panel options

We understand that different applications require different silo sizes. Our silos range from 1.83 metres to 30.95 metres in diameter and up to 5.37 metres in height. This variety ensures that we can accommodate any capacity requirement, whether you need 30 cubic metres or 2000 cubic metres.

Our silos come with options for long panels, which are 3.05 metres wide, and short panels, measuring 2.24 metres wide. While long panels are suitable for certain applications, short panels are more convenient for containerised shipping, making loading and unloading easier. This flexibility allows us to tailor our solutions to your logistical needs.

Robust construction with M12 bolts

To ensure the highest level of structural strength, we use M12 bolts for all our silos. These bolts offer significant advantages in terms of shear strength, enhancing the overall stability and durability of the silos. This choice reflects our commitment to providing robust and reliable water storage solutions that stand the test of time.

Versatile installation methods

Our silos can be installed using various methods to suit different site conditions. They can be placed on a concrete rim, a full concrete base, or paving tiles. For installations on concrete bases, anchor brackets are needed for added stability. When the silo is built on tiles, a sand ridge must be placed against the silo, or the silo must be dug in 50 cm. The bottom ring of the silo must then be provided with an extra coating to prevent corrosion.

Indoor and outdoor applications

Genap silos are designed to perform in both indoor and outdoor settings. For indoor installations, we offer a wider range of cover options, such as low-cost tensioned covers that prevent algae growth, evaporation, and debris accumulation. Outdoor installations require more consideration of environmental factors like wind, snow, and rain. Our cover options, including floating covers, tensioned covers, domes, and fully enclosed systems like the GenaFlexstore®, ensure that our silos can withstand these conditions while maintaining water quality.

Precision engineering and static calculations

Each Genap silo undergoes rigorous static calculations by independent engineers. Using advanced software, we ensure that our silos have a safety margin of at least 20%. This meticulous process allows us to determine the optimal steel thickness for different diameter and height combinations, ensuring that our silos are both safe and efficient.

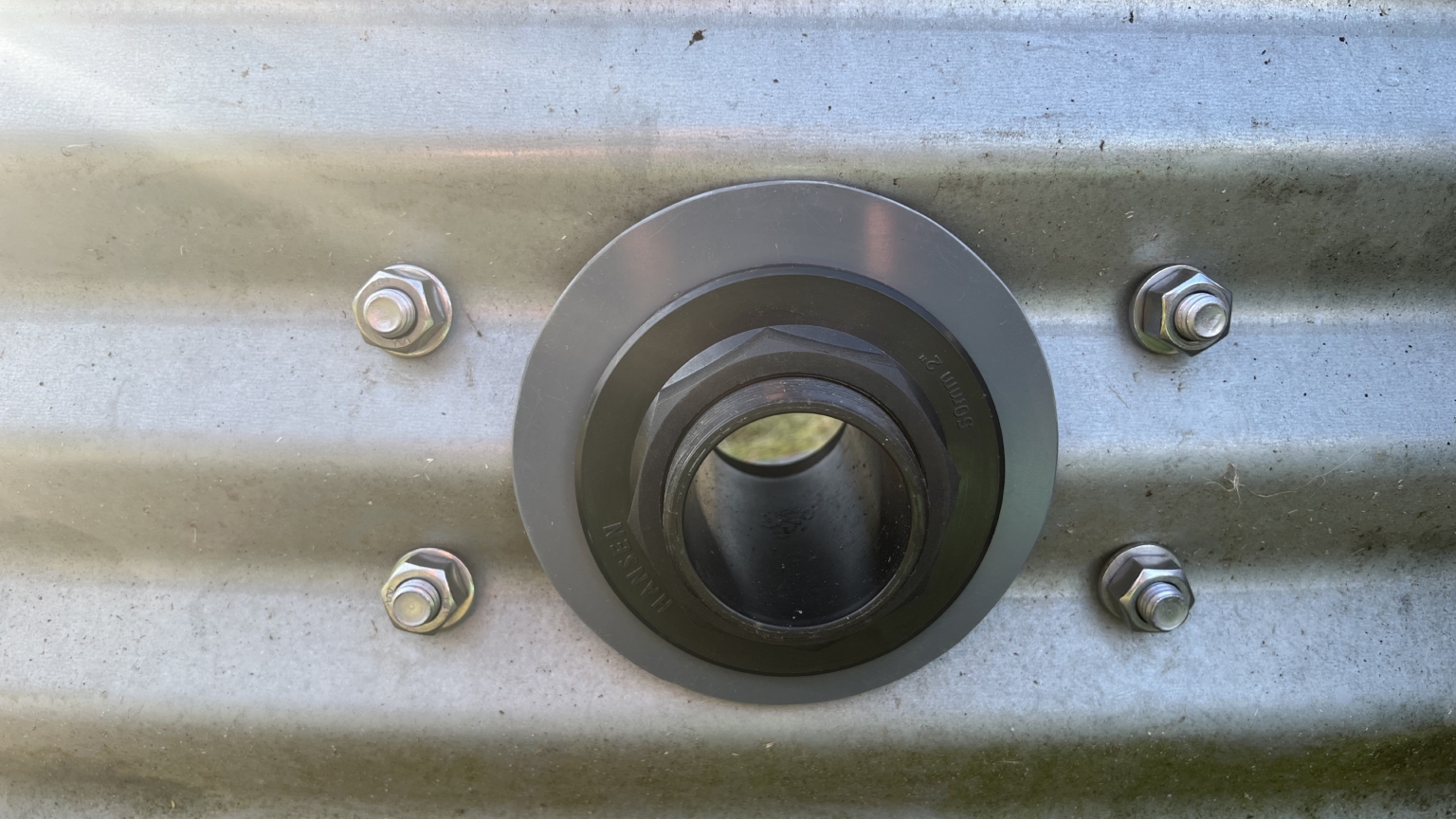

Comprehensive outlet and liner options

We offer a variety of outlet configurations, including conical and mechanical outlets through the base or side of the silo. This range allows you to select the best option for your needs, whether it’s for complete water removal or sediment management.

Our liners are tailored to different water types, including drinking water, groundwater, clean water, and dirty water. Depending on your requirements, we provide liners made from PVC, polyethylene, or polypropylene, ensuring compatibility and safety.

Adaptability to weather conditions

Genap silos are designed to function effectively in all weather conditions. Especially for windy areas, we recommend the GenaFlexstore® or floating covers that sit below the silo edge, avoiding wind exposure. In areas with heavy rain, we suggest using the GenaFlexstore®, the Genadome, or floating covers to manage water effectively. High UV exposure areas benefit from our floating covers that prevent algae growth and evaporation.

Silos vs. reservoirs: Making the right choice

Choosing between silos and reservoirs depends on your specific needs and space constraints. Silos are ideal for limited spaces, offering significant water storage with a minimal footprint. For larger storage needs, combining lagoons and silos is often the best solution. Lagoons can handle bulk storage, while silos can serve as day silos or three-day silos, ensuring water cleanliness, appropriate temperature, and availability.

In conclusion, our deep understanding of the complexities involved in water storage allows us to provide professional growers with tailored, reliable, and durable solutions. At Genap, we are dedicated to ensuring that your water storage needs are met with precision and care, no matter the conditions.